|

|

| |

KOTELYZER (Cordless Soldering Iron) |

SK-70 Series |

|

|

|

|

Multi-holder

creates new

field of

cordless

soldering

iron |

|

|

|

|

SKC-70

|

|

Two-in-one heat tool

with soldering and hot

blow functions |

SKC-70

●Body with

SK-71 tip

●Multi-holder

●SK-84 Hot

blow tip

●Protective

cap |

|

|

|

|

|

|

SKD-70

|

|

Designed to perform

telecommunication work |

●Body

with SK-79

tip

●Multi-holder

●SK-72

Chisel tip

●Protective

cap |

|

|

|

|

|

|

■ SKD-70 set comes with a high-power

tip for cable maintenance work and an accurate tip

for telephone office service |

SK-70

Comes with steel-made soldering stand box

Angle of soldering stand adjustable (3 steps)

●Body with SK-71 tip ●Cleaner sponge

●SK-84 Hot blow tip ●Soldering stand |

|

|

|

● No electricity required. Ideal for in-field

service and maintenance where instant heat is

required

● Super quick heat up with one-touch operation

● Completely cordless assures no electric leakage

and no E.M.I

● Flameless and safe heat generating system by

patented gas catalyst reaction

● Variable temperature control (equivalent to 20-80W

electric soldering iron) |

|

|

|

|

Three functions of Multi-Holder assures

safe and wide task field !! [PAT.P] |

|

|

|

|

|

|

| 1. Iron Stand |

2. Magnetic attachment |

3. Hanging from cable |

|

|

|

|

|

|

|

Ceramic coating made on tip and tip housing |

|

|

SKS-70

●Body with SK-38 ceramic tip ●Multi-holder

●Protective cap |

|

|

|

|

PAT. |

|

|

|

|

|

Maintenance of Switch-board |

Soldering on terminals |

|

|

● Safety

soldering

work to

prevent

short-circuit

caused by

mis-contact

with dense

terminals

● Ideal for

Telecommunication

field

(switch-board

maintenance

etc.) |

|

|

|

|

■SK-70 Series

Specifications |

|

System |

Gas Catalyst

Reaction System |

Thermal

Output |

Soldering Iron

|

Max. 500℃

approx. |

|

Equivalent to

20~80W electric

soldering iron |

|

Hot Blow |

Max. 650℃ |

|

Gas tank

capacity |

28cc |

Operation time

for

one fill of gas |

About 2 hours

(Lever position:

3)

About 4 hours

(Lever position:

2) |

|

Overall Length

|

265㎜ |

|

Net Weight |

110g |

|

|

■SK-70 Series

Accessories Contained |

|

Model |

Soldering Tip

|

Hot Blow Tip

SK-84 |

Protective

Cap

|

Multi-

holder

|

Steel

Case

|

|

SK-71 |

SK-72 |

SK-79 |

SK-38 |

|

SK-70 |

● |

|

|

|

● |

|

|

● |

|

SKA-70 |

● |

|

|

|

● |

● |

|

|

|

SKB-70 |

● |

|

|

|

● |

|

|

|

|

SKC-70 |

● |

|

|

|

● |

● |

● |

|

|

SKD-70 |

|

● |

● |

|

|

● |

● |

|

|

SKS-70 |

|

|

|

● |

|

● |

● |

|

|

| |

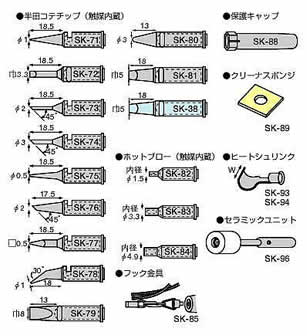

REPLACEMENT PARTS |

SK-70 Series |

|

|

|

|

|

Model |

Description |

|

SK-38 |

5mm

Chisel

(Ceramic

Coating) |

|

SK-71 |

dia.

1mm

Tapered

needle

|

|

SK-72 |

3.3mm

Chisel |

|

SK-73 |

dia.

2mm

spade |

|

SK-74 |

dia.

3mm

spade |

|

SK-75 |

dia.

0.5mm

Tapered

needle |

|

SK-76 |

dia.

2mm

spade |

|

SK-77 |

0.5mm

Tapered

pyramid |

|

SK-78 |

dia.

1mm

Curved

tapered

needle |

|

SK-79 |

8mm

High

powered

chisel |

|

SK-80 |

3mm

High

powered

round

needle |

|

SK-81 |

5mm

High

powered

taper

chisel |

|

SK-82 |

dia.

1.5mm

Hot

blow

tip |

|

SK-83 |

dia.

3.3mm

Hot

blow

tip |

|

SK-84 |

dia.

4.9mm

Hot

blow

tip |

|

SK-85 |

Hook

fitting

|

|

SK-88 |

Protective

cap

|

|

SK-89 |

Cleaner

sponge |

|

SK-93 |

Heat

Shrink

W-22mm |

|

SK-94 |

Heat

Shrink

W-18mm |

|

SK-96 |

Ceramic

unit

|

|

|

|

|

| |

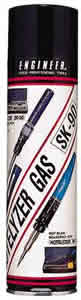

REPLACEMENT PARTS |

SK-90?95 |

|

|

|

|

Butane liquefied

odorless gas for

industrial use |

|

|

|

|

|

|

SK-90 265cc |

SK-95 480cc |

|

|

|

|

TOP |

| |